Next Generation

Mechanical Testing

Unravelling the unknown & aiding groundbreaking research.

Create innovative products which aid in augmented materials research.

Partner with academia and industry to enhance product capabilities.

Make our technologies accessible to all research institutes.

Strategically expand the horizon of materials testing and characterization.

Testing in-service components are essential to understand their failure. This helps design new materials, manufacturing methods, and parts. Miniaturised testing allows site-specific testing, which is vital to comprehend material under the thermal and mechanical stresses during manufacturing. Additive manufacturing also demands site-specific testing because of its inherent nature.

In-situ characterization augments the information obtained as it is carried out under real-time loading. The vital information collected is essential for identifying the failure mechanism and allows material manufacturers to design new materials. Here it is employed for measuring single crystal elastic constants for new materials that are challenging and expensive to determine otherwise.

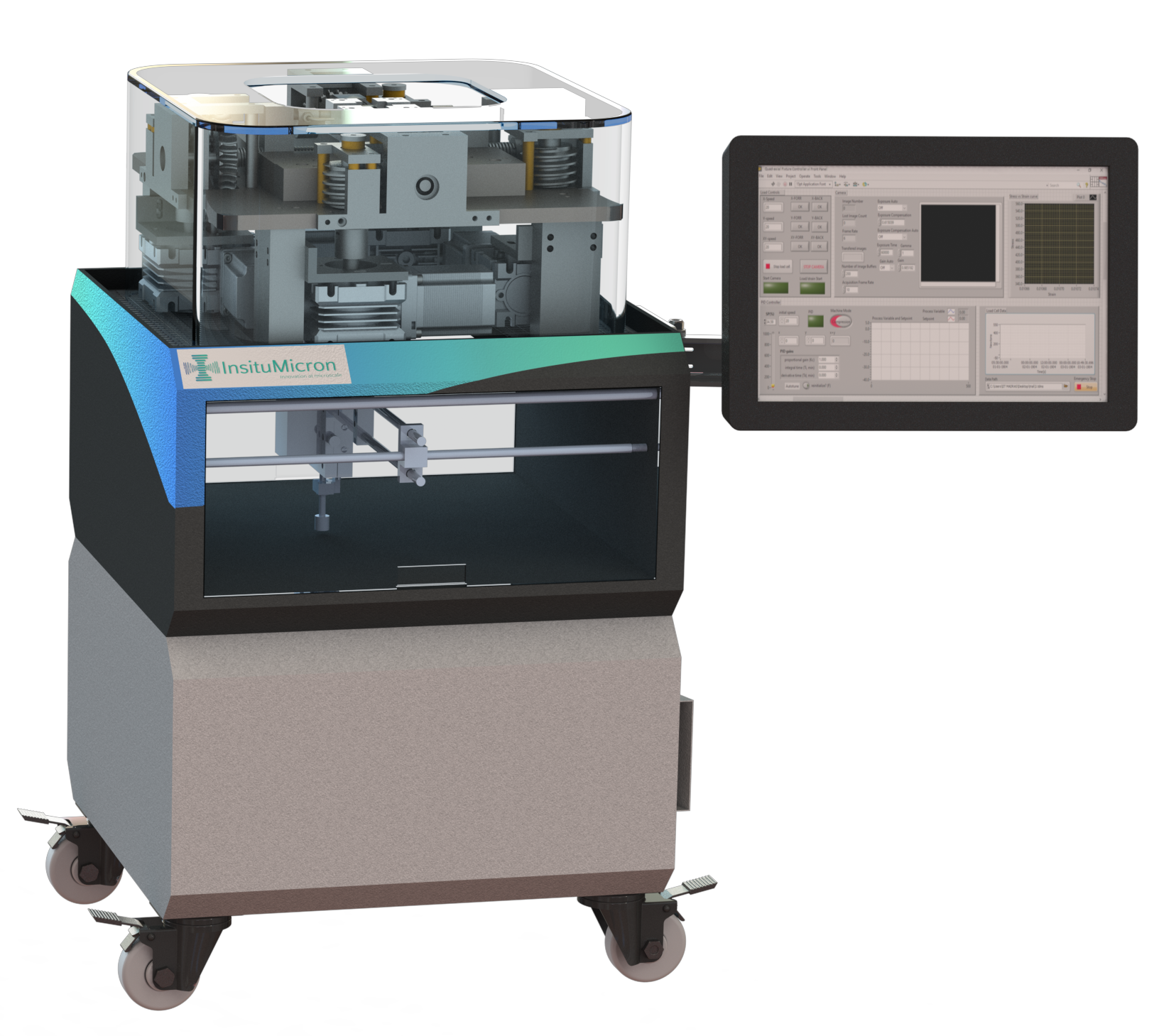

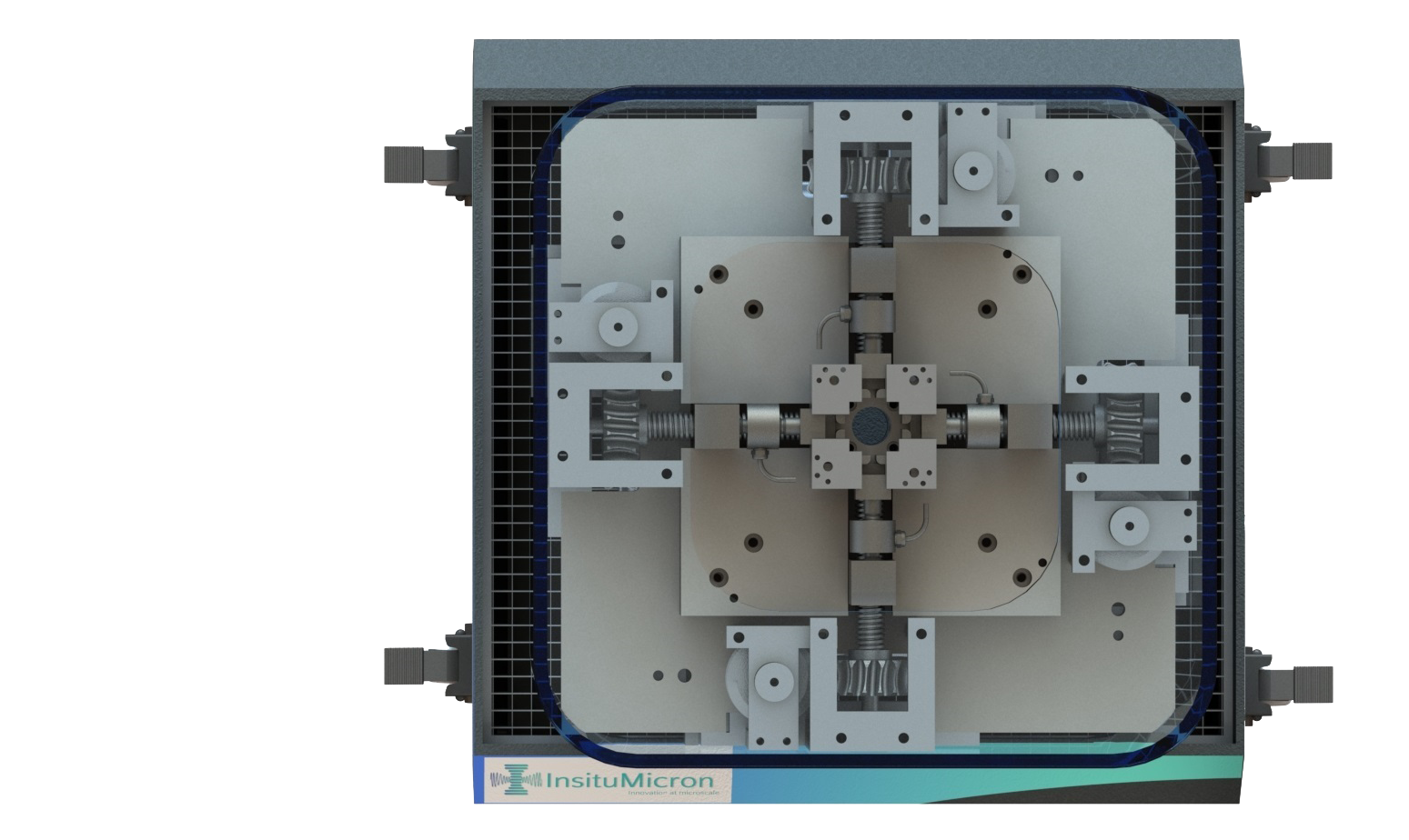

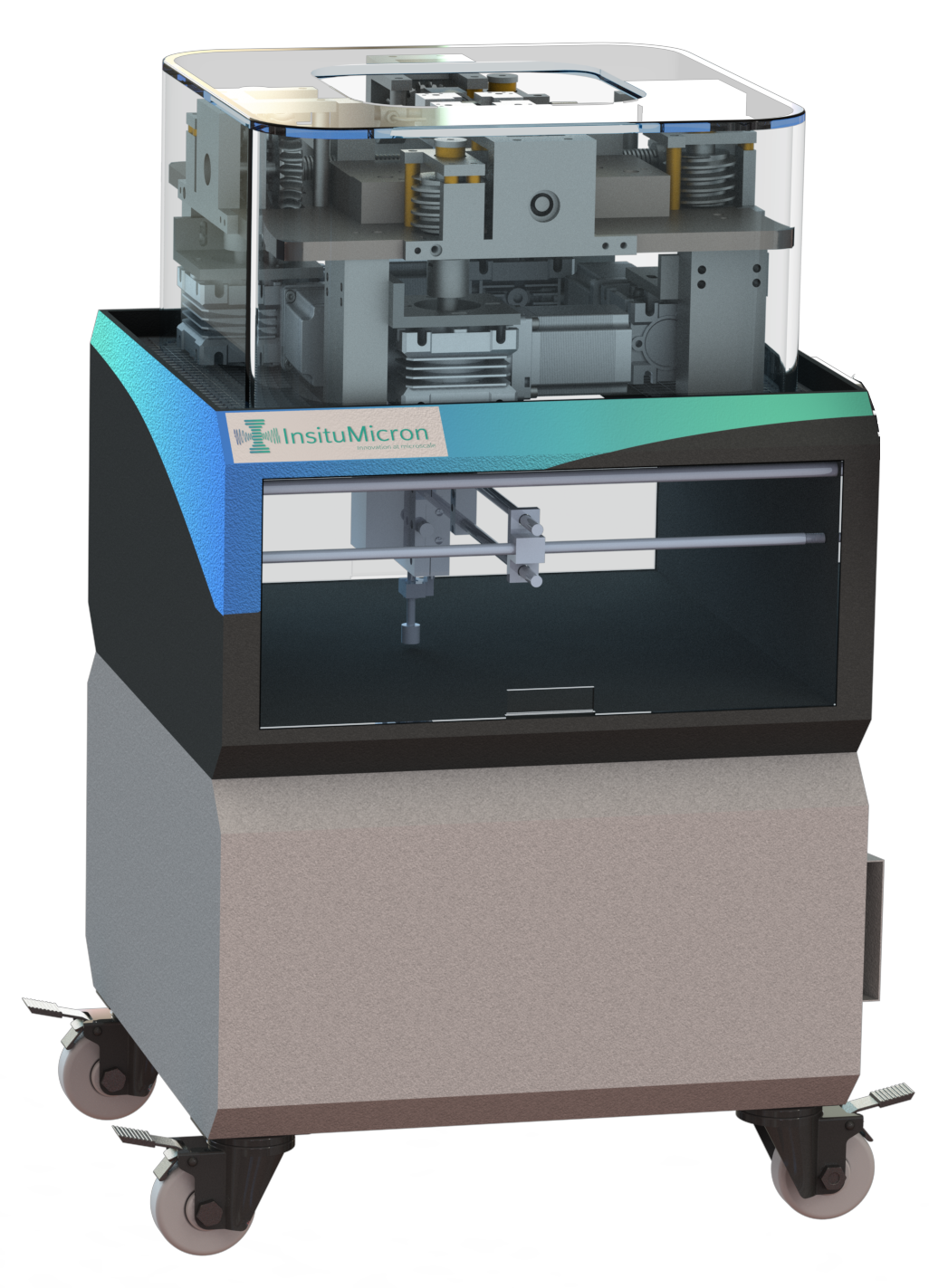

The novel miniature fixture design allows for seamless integration into characterization equipment.

Our innovative clamp design made testing tension, compression, and bending modes possible.

The perfectly optimized system makes our equipment produce reliable and consistent results.

Our custom-built software is easy-to-use which makes testing effortless.

Stress-strain behaviour, Strain hardening and Plastic anisotropy.

Strength of brittle materials, toughness and deformation behaviour.

Bending strength, Fracture toughness, crack propagation.

Finding single crystal elastic constants, stress-induced phase changes and strain partitioning.

Localized changes in chemical bonding and deformation mapping.

Understand failure mechanisms and microscale deformation analysis.